Title: A DESIGN PLAN FOR ELECTRICITY MINIGRID POWERED BY HYBRID ENERGY STSTEM FOR RURAL ELECTRIFICATION

Authors:

Sumit Sanjay Pawar, BE Mechanical-Year 4, Smt. Kashibai Navale College of Engg, Pune

Rohit Ashokrao Kasle, BE Computer-Year 4, Sinhgad College of Engg, Pune

Gauri Sunil Kolhe, BE Computer-Year 4, Sinhgad College of Engg, Pune

ABSTRACT – Rural electrification is an important component of integrated rural development. The best technical approach for electrification of rural areas is establishing a minigrid powered by hybrid energy system. Hybrid energy system is a combination of both renewable and non-renewable energy resources, which insures maximum availability of electricity with minimum cost. This paper presents a design plan for power generation in rural areas. The prerequisites for design plan are the details about the area under study, available renewable energy resources and energy demand of that area. By studying the gathered information design plan can be implemented via following steps: addition of non renewable energy resources to the minigrid, sizing the power plant, cost per unit estimation, optimization (if necessary) and final model formation.

KEYWORD – renewable energy, non-renewable energy, hybrid energy system, electricity home system, minigrid, cost estimation, optimization, solar, wind, hydro, biomass.

I] INTRODUCTION:

Rural Electrification is increasingly becoming a household necessity for eradicating the energy crisis confronted by the people living in remote areas. Around 70% population of India [1] lives in rural areas contributing 14% to the Indian economy (Source: Database on Indian Economy – RBI). As of today 46% rural households (Source: As of December 2011, Rural Electric Corporation) has been electrified but it lacks both quality and quantity with an extensive shortfall in supply and transmission & distribution losses.

There are basic three technical approaches to bringing electricity to remote areas [2]: A first option is to extend the national electricity grid. But comparing to the thin population of rural areas, small energy demand, difficult terrain to reach there and far away distance from urban area, it is not a feasible solution. The second approach is through Electricity Home System (EHS), it consists of small energy generating devices designed for a particular application or to power individual household. The third option is based on electricity minigrid which can provide electricity generation at local level and supposed to power a cluster of villages. In simple words, it is mini version of national electricity grid and the upgraded version of electricity home system. A minigrid can be supplied by either renewable or non renewable energy resources or both combined together (Hybrid Energy System).

II] HES MINIGRID:

As the name suggest, Hybrid Energy System (HES) is a combination of both renewable energy resources like solar, wind, hydro, biomass and non renewable one most likely diesel generators. Following table shows a comparative study of different electricity supply options for rural electrification with the advantages HES minigrid:

TABLE 1: ELECTRICITY SUPPLY OPTIONS FOR RURAL ELECTRIFICATION

|

OPTIONS |

DRAWBACKS |

HES MINIGRID ADVANTAGES |

| National Grid |

|

Energy generation is at local level |

| Minigrid powered by only non-renewable sources |

|

|

| Minigrid powered by renewable sources |

|

|

For designing a minigrid for rural areas, some constraints should be followed like maximum efficiency of power plant, maximum availability, low cost per unit, low initial cost, low maintenance cost, maximum span of life and easy to expand. Studying pros and cons of available electricity supply options and constraints on design of a power plant, it is clear that, if we have a properly designed power plant which utilizes both renewable and non-renewable energy recourses, where one recourse type can overcome the cons of the other one, it can definitely ensure maximum availability of electricity.

III] PREREQUISITES FOR DESIGN PLAN:

Before deciding the prerequisites for design plan of HES minigrid, we must go through some of the features of Rural Electrification because of which it has not given due importance until now [3]: villages are located 3-30 km away from the existing grid or even more, located in difficult terrain areas, power demand in villages is quite low with poor load factor and the income level is low hence the paying capacity. On the analysis of above features some of the prerequisites on which the success of design plan of a HES minigrid depends are: details of the area under consideration, available renewable resources in that area and demand by consumers in that area.

1] SELECTION OF AREA:

First step is to select such a village, where it is not possible to extend the national electricity grid. Generally the water reservoirs (for hydro power station), high altitude sites (for solar and wind) are common to number of villages. So HES minigrid can be designed for such a cluster of villages. If in some of the cases the villages are not reasonably accessible due to far more distance or difficult terrain minigrid can be designed for individual village.

2] RESOURCE ASSESSMENT:

The renewable resources like solar, wind and biomass are freely available almost everywhere but resources like hydro, geothermal and tidal energy are very site specific. As these resources are intermittent, details about their availability throughout the year with the energy amount is calculated. Suggested thresholds for different resources for determining feasibility are given in following table [4]:

TABLE 2: THRESHOLD AMOUNT OF A SITE RESOURCE TYPICALLY NEEDED FOR FEASIBILITY

|

SITE RESOURCES |

TYPICALLY NEEDED |

| Full Sunlight (hrs/day) | 2 hr/day more |

| Wind Speed (m/s) | 4 m/s or more |

| Stream Speed (m/s) | 1 m/s or more |

| Biomass | Depend upon no. of cattle (24kg ≈ 1kWh) |

3] DEMAND ASSESSMENT:

Total energy demand of villages is categorized into two types’ Primary load and Desirable load. Primary load consists of domestic needs and community needs like schools, clinics, Panchayat Samiti, street lamps and holy places. Desirable load consists of agricultural load (pumps, other machinery etc.) and small industrial load (flour mill, mini water purification plants) Following table illustrates the peak energy demand by above mentioned categories throughout the day:

TABLE 3: PEAK ENERGY DEMAND THROUGHTOUT THE DAY

| DAWN | MORNING | AFTERNOON | EVENING | NIGHT |

| Agricultural load | Domestic load | Agricultural load,

Industrial load |

Community load | Domestic load |

IV] DESIGN PLAN:

Design plan is an output of following procedure: estimation of energy amount required by diesel generators, sizing the power plant, cost estimation, optimization (if necessary), and model formation.

1] DIESEL GENERATOR:

Diesel Generator sets are the most common source of electric power in rural areas .The reason that diesel generator sets are so common is probably that they are inexpensive to purchase and they can be installed at almost any place. Disadvantage with them are high operating costs and maintenance problems. Diesel generators are integrated with HES minigrids for following reasons:

• To compensate for variation in energy demand which fluctuates time to time

• To balance the intermittent energy supply of renewable sources

• As a backup source in case of any system failure and system maintenance

The environmental effects of diesel generators are more or less obvious. Diesel is a fossil fuel, which means that combustion leads to pollution of carbon dioxide, nitrogen oxides and sulphur dioxides. But in rural areas it will not be a major threat to the local environment.

2] SIZING THE POWER PLANT:

Sizing the power plant is nothing but deciding the energy contribution in grid by each resource type. Following table shows the cost per unit electricity generation by different resource type [5]:

TABLE 4: TECHNOLOGY OPTIONS WITH COST OF SUPPLY

|

TECHNOLOGY |

PROS AND CONS |

COST OF SUPPLY RS/KWH |

| Grid Electrification | Cheap, clean, low maintenance.

Costly to supply, high T&D losses, poor quality. |

3-5 |

| Diesel generator sets | Low initial cost, Continuous energy services.

High fuel costs and emissions |

8-10 |

| Small biomass plant(50-100kW) | Allows income generating activities, Base load operation.

Carbon emissions in some cases, Limited resource. |

6-8 |

| Micro-hydro(50-100kW) | Long-life, Reliability, low maintenance.

Limited resource availability, Seasonal variation in supply. |

3-7 |

| Wind-hybrid

(50-100kW) |

Reduced fuel cost, flexible load.

Relatively cost effective renewable where strong wind resource. Serious location problems. |

8-10 |

| Bio-fuel powered generator

(Bio-diesel, 50-100kW) |

Base load operation, Continuous operation possible.

Carbon neutral, Fuel supply issues. |

8-15 |

| Solar PV Panels | No fuel cost, Totally environment friendly.

High initial cost and battery replacement cost. |

25+ |

The major goal of “sizing the power plant “is to match the resources with the demand of energy. Sizing the power plant is nothing but combining and manageing the different energy resources in correct proportion in order to maximize the performance of plant which leads to minimization of the cost per unit. Over sizing and under sizing the capacity of plant will result in unnecessary cost and load stress respectively [6]. Over-sizing leads to increasing the capital cost and producing surplus of electricity which is not used. Under-sizing results in unavailability of power which results in load shedding.

Over-sizing can be beneficial in some ways, if in future the energy demand is likely to increase. Rural electrification is intended for rural development which in turn increases their energy demand in future. If future increase in demand is not accounted while sizing the plant then the ultimate goal of rural development is not achieved.

3] COST ESTIMATION:

The income level in rural areas in low and hence the paying capacity. The cost estimation includes the initial investment cost, operational cost (fuel cost) and maintenance cost. Estimation of cost of energy are made on annual basis and given as [7, 8]:

Where, C = cost of energy in Rs/kWh

k = Annual capacity factor per unit

n = Amortization period (lifetime of the system) in years

O & M = Operation and maintenance cost (in Rs/kWh)

P = Installed Capital Cost (in Rs/kW)

r = Fixed annual cost in per unit (in 0.01 Rs/kWh)

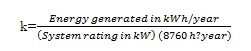

Capacity factor refers to the ability of the system to generate energy on an annual basis. It is found using:

The following relation may find the cost per unit of diesel generated power [9]:

Where, CD= Cost of diesel generated power in Rs/kWh

CF= Diesel fuel cost in Rs/liter

P = Diesel generator electric power output in kW

Fi= Incremental diesel fuel consumption rate in liters/hr

F0= Diesel generator fuel consumption at no load in liters/hr

4] OPTIMIZATION:

The main objective of the optimization step is to reduce the cost per kWh. After the cost per unit estimation is done, it checked for any optimization is possible. As cost of supply of each resource type if different and vary from Rs.3 to Rs.25, the final cost depends on the percentage contribution of each technology. Some optimization techniques that should be followed are:

Resources which require batteries for storage should have appropriate contribution to the grid coz of high initial cost and maintenance of batteries.

Mini hydro plant must be implemented wherever possible due to it’s free of cost fuel and low maintenance.

Diesel generators should be operated near to the full load capacity to achieve maximum efficiency.

Continuous accurate assessment of demand and supply in order to carry out best possible improvements in the system.

5] MODEL FORMATION:

A general HES minigrid model can be formulated on the basis of linear programming as [10]:

Where, TC = Total cost of providing energy for all end uses for operation of the system

Cij = cost/unit of the ith resource option for jth end use (Rs/kWh)

Xij = optimal amount of the ith resource option for jth end use (Rs/kWh)

Dj = total energy for jth end use (kWh)

Rij = optimal amount of the ith resource option for jth end use (Rs/kWh)

Pi = total availability of the ith renewable resource option for jth end use (kWh)

Si = Availability of the ith resource option for jth end use (kWh)

ᶯij = conversion efficiency for the ith resource option for jth end use.

V] CONCLUSION:

This paper provides a summary of available approaches and methodology for harnessing renewable energy resources in rural electrification. Proposed system consists of a design plan for the cost effective power generation in rural areas via electricity minigrid powered by hybrid energy system. Success of the design plan greatly depends on gathering of the prerequisites information which leads toward the cost estimation, sizing and optimization of the power plant. Further study is required on the expansion of the minigrid to cope up with the increased demands in future.

VI] REFERENCE:

www.tradingeconomics.com/india/rural-population-percent-of-total population-wb-data.html

www.ruralelec.org/38.0.html#c3303

Kamalapur G D, Udaykumar R Y, Karajgi S B, “Strategies for sustainable electrification in India,” Proc. Of International Interdisciplinary Conference on sustainable Technologies for environmental protection, Coimbatore, 7-9, January 2006

M.G. Green, “How to generate electricity in remote areas: A simple guide to choosing the right technology”, M.S. thesis, Dept. Mech. Eng., Texas Univ., Austin, 2002.

James Cust, Anoop Singh, Karsten Neuhoff, “Rural Electrification in India – Economic and Institutional aspects of Renewables”

www.ruralelec.org/38.0.html#c1936

R. Ramakumar and W.L. Hughes, “Renewable energy sources and rural development in developing countries,” IEEE Transactions on Education, vol. E-24, No. 3, pp.242-251, August 1981

M.Ashari, C.V. Nayar and W.W.L. Keerthipala, “Optimum operation strategy and economic analysis of a photovoltaic diesel battery mains hybrid and uninterruptible power supply,” Renewable Energy, vol. 22, pp.247-254, 2001

C.D. Barley, C.B. Winn, “Optimal dispatch strategy in remote hybrid power system,” Solar energy, vol. 58, No. 4-6, pp.165-179, 1996

Ajai Gupta, R.P. Saini, M.P. Sharma, “Hybrid Energy System for Remote area – An action Plan for Cost Effective Power Generation,” IEEE Region 10 Colloquim and the Third ICIIS, Kharagpur, India, 2008