Title: A study Paper on Power Hump

Authors: P.Chandra Sekhar,A.Balasubrahmanyam & K.Rajashaker Reddy, 2nd Year BTech, Electrical and Electronics Engineering

Guide: Prof. Meeravali, Department of Electrical and Electronics Engineering

College: PRAKASAM ENGINEERING COLLEGE, KANDUKUR

1. ABSTRACT:

In the present scenario power becomes major need for human life. Due to day –to-day increase in population and lesser of the conventional sources, it becomes necessary that we must depend on non conventional sources for power generation. While moving, the vehicles posses some kinetic energy and it is being wasted this kinetic energy can be utilized to produce power by using a special arrangement called “POWER HUMP”. The energy of moving vehicles can be converted into mechanical energy of the shaft through rack and penion mechanism. This shaft is connected to the electric dynamo and it produces electrical energy promotional to traffic density. This generated power can be regulated by using zener diode used for general purpose like streetlights, traffic signals. The electrical output can be improved by arranging these power humps in series this generated power can be amplified and stored by using different electric drives. The maintenance cost of hump is almost nullified. By adopting this arrangement, we can satisfy the future demands to some extent.

2. INTRODUCTION:

The availability and its per capita consumptions are regarded as the index of national standard of living in the present day civilization. Energy is an important input in all the sectors of any countries economy. Energy crisis is due to two reasons, firstly the population of the world has been increased rapidly and secondly standard of living of human beings has increased.

India is the country, which majorly suffers with lack of sufficient power generation. The capital energy consumption of U.S.A is about 8000 K.W.H., whereas per INDIA is only 150 K.W.H. U.S.A. with 7% of world population consumes 32% of world population consumes 32% of total power generation where as INDIA as developing country with 20% of world population consumes only 15 of total energy consumed in the world. The availability of regular conventional fossil fuels will be the main sources for power generation, but there is a that they will get exhausted eventually by the next few decades. Therefore, we have to investigate some approximate. Another major problem, alternative, new sources for the power generation, which is not deflected by the very few years, which is becoming the exiting topic for today is the pollution. It suffers all the living organisms of all kinds as on the land, in aqua and in air. Power stations and automobiles are the major pollution producing places. Therefore, we have to investigate other types of renewable sources, which produce electricity without using any commercial fossil fuels, which is not producing any harmful products. There are already existing such systems using renewable energy such as solar wind), OTEC (ocean thermal energy conversions) etc… for power generation. The latest technology which is used to generate the power by such renewable energy is the “POWER HUMP”.

Now I m throwing some light on the very new and innovative concept i.e. GENERATING ELECTRICITY FROM A SPEED BREAKER.

3. NEED FOR THE MODEL:

An energy crisis in any great bottleneck in the supply of energy resources to any economy. It is usually refers to the shortage of oil and additionally to electricity or other resources. An energy crisis may be referring erred to as an oil crisis, petroleum crisis, energy shortage, electricity shortage electricity crises. While not entering a full crisis, political riots that occurred during the 2007 Burmese anti government protests were initially sparked by rising energy prices. Likewise the Russia-Ukraine gas dispute have and the Russia Belarus energy dispute have been mostly resolved before entering a prolonged crisis stage. Market failure is possible when monopoly manipulation of markets occurs. a crisis can develop due to industrial actions like union organized strikes and government embargoes. The cause may be ageing over consumption, infrastructure and sometimes bottlenecks at oil refineries and port facilities restrict fuel supply.

2008 central Asia energy crisis caused by abnormally cold temperatures and low water levels in an area dependent on hydroelectric power.

South African electrical crisis solution for Energy Crisis Next time on the roads, don’t scoff at the speed-breakers. They could actually light up small villages off the highway. This project is about GENERATION OF ELECTRICITY with the SPEED BREAKRS.

The speed breaker on a busy road will be lifted from one side and fixed on the other side. There will be a crankshaft mechanism below the speed breaker. The shaft of the generator will be attached to the disc and the road connected to the disc from the speed breaker (rotation can be increased by using gears).

The protype made using a simple dc motor gave an unbelievable output of 12 volts. And the cost of the prototype was just 400 rs .the idea can be applied on heavy traffic road.

4 .STATISTICS ON LOAD AND POWER GENERATION:

“When the vehicle moves over inclined plates, it gains height resulting in increase in potential energy, which was wasted in a conventional rumble strip, “we say.”When the plates come down, they crank a lever fitted to a retched-wheel type mechanism. This in turn rotates a geared shaft loaded with recoil springs. The output of the shaft is coupled to a dynamo to convert kinetic energy into electricity,”

“A vehicle weighing 1,000 kg going up a height of 10 cm on such a rumble strip produces approximately 0.98 kilowatt power. So one such speed breaker on a busy highway, where about 100 vehicles pass every minute, about one kilo watt of electricity can be produced every single minute. The figure will be huge at end of the day,”

A dynamo, originally another name for an electrical generator, now means a generator that produces direct current with the use of commutator. This DC is converted into AC by inverter.

5. DESCRIPTION:

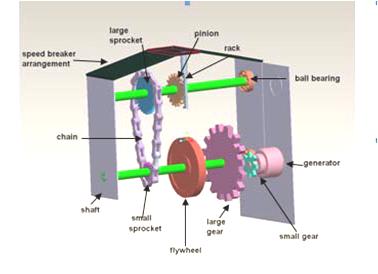

Constructional details:

1. Rack 2.Shaft

3. Pinion 4.Cast iron

5. Wheel 6.Springs

The dynamo uses rotating coil of wire and magnetic fields to convert mechanical rotation into pulsing direct electric current through faraday’s law. On small machines the constant magnetic field may be provided by one or more permanent magnets; larger machines have the constant magnetic field provided by one or more electromagnets, which are usually called field coils.

Dynamo’s were invented as a essentially a rotary switch capable of an extremely large number of make and break operations. It consists of a set of contacts mounted on the machines shaft, combined with graphite-block stationary contacts, called “brushes”, because the earliest such fixed contacts were metal brushes. The commutator reverses the connection of the windings to the external circuit when the potential reverses, so instead of alternating current, a pulsing direct current is produced.

6. WORKING PRINCIPLE:

While moving, the vehicles posses some kinetic energy and it is being wasted. This kinetic energy can be utilized to produce power by using a special arrangement called POWER HUMP. It is an electro-magnet unit. It utilizes both mechanical technologies and electric techniques for the power generation and its storage. POWER HUMP is a dome like device likely to be sapped breaker.

Whenever the vehicle is allowed to pass over the dome it gets pressed downwards then the things are attached to the dome are compressed and rack which is attached to the bottom of the dome moves downward in reciprocating motion. Since the rack has teeth connected to gears, there exists conversion of reciprocating motion of rack into rotary motion of gears but the two gears rotate in opposite direction. A flywheel is mounted on the shaft whose function is to regulate the fluctuation in the energy and to make the energy uniform. So that the shaft will rotate with certain R.P.M these shafts are connected through a belt drive to the dynamos, which converts mechanical energy into electrical energy. The conversion will be proposional to traffic density.

Whenever an armature rotates between the magnetic fields of south and north poles, an E.M.F (electro motive force) is induced in it. So, for inducing the E.M.F. armature coil has to rotate, for this armature it is connected to a long shaft. By rotating same e.m.f, is induced, for this rotation kinetic energy of moving vehicles is utilized. The power is generated in both the directions; to convert this power into one way a special component is used called zenor diode for continuous supply. All this mechanism can be housed under the dome, like speed breaker, which is called HUMP. The electrical output can be improved by arranging these POWER HUMPS in series. This generated these POWER HUMPS in series. This generated power can be amplified and stored by using different electrical devices.

7. OUTPUTPOWER CALCULATIONS:

Let us consider,

The mass of a vehicle moving over the speed breaker =250Kg (Approximately)

Height of speed brake =10 cm

Work done=Force x Distance

Here,

Force=Weight of the Body

=250 Kg x 9.81

=2452.5 N

Distance traveled by the body = Height of the speed brake=10 m

Output power=Work done/Sec

= (2452.5 x 0.10)/60

4.0875 Watts (For One pushing force)

Power developed for 1 vehicle passing over the speed

Breaker arrangement for one minute= 4.0875 watts

Power developed for 60 minutes (1 hr) =245.25 watts

Power developed for 24 hours=5.866 KW

This power is sufficient to burn four street lights in the Roads in the night time.

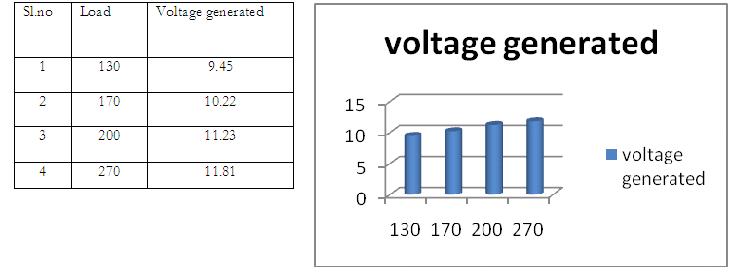

Load vs. voltage generated

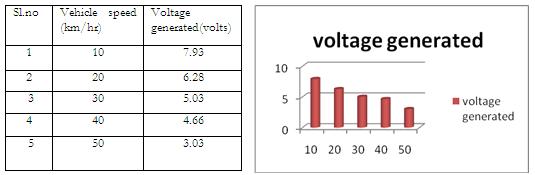

Speed VS voltage generated

8. ADVANTAGES:

• Pollution free power generation.

• Simple construction, mature technology, and easy maintenance.

• No manual work necessary during generation.

• Energy available all year round.

• No fuel transportation problem.

• No consumption of any fossil fuel which is non renewable source of energy.

9. DISADVANTAGES:

• We have to check mechanism from time to time.

• It can get rusted in rainy season.

• It will not work with light weight vehicle.

10. CONCLUSION:

Energy is an important input to sustain industrial growth and standard of living of country and can be directly related to per-capita energy like coal, oil, uranium etc…..are depleting very fast and by the turn of the century man will have to depend upon nonconventional sources of for power generation. The various types of non-conventional sources of energy are solar energy, wind energy, biogas etc… now by developing “POWER HUMP” we can generate power without utilizing any external sources mentioned earlier.

Now, vehicular in big cities is more, causing a problem to human being. But this vehicular traffic can also be utilized for power generation by means of new technique called “POWER HUMP”. It is placed in heavy traffic roads, the weight and kinetic energy of the vehicles can be used to produce mechanical power in shafts and this mechanical power once again converted into electrical energy. As it does not utilize any external source, and traffic will never be reduced, these power humps are more reliable, and have more life than any other power source. It is also feasible from the customer point of view as follows the total installation cost of the hump is 6000 rupees. Total cost=6000 rupees say with improvements in design it can glow 5 streetlights of 30-watts capacity, which will consume 2.7 K.W.H. per day.

For t years electricity bill will be 2986.5*t T=2years i.e. the consumer will be repaid his investment and free of cost. The life of POWER HUMP is estimated to be 6 years. So the customer will get free power for 4 years period. But major drawback of this POWER HUMP is design of springs. When we have less traffic and there is difficulty in design of spring as also the generation of power is intermittent, we have to smooth out this variation. With proper improvements in design and installation, we can produce 240v/230v with 5-10A power smoothly and can be used for public use like street lights or traffic signals.

11. REFERENCE:

1. Department of transport (UK) highway (road humps)

2. R. S khumi (machine design)

3. Sharma aggrawal (machine design)

4. Shigley R, Tata MC Graw hills(machine design)

5. G.D Rainon conventional energy sources