Title: HI-5 TECHNIQUES TO REDUCE CO2 FROM CEMENT INDUSTRY

Authors: S.HARISUDHAN , 3rd Year B.E, Civil Engineering Department

M.NARMATHA, 3rd Year B.E, Computer Science Engineering Department

College: Indra Ganesan College of Engineering , Trichy

ABSTRACT:

Cement and concrete sector is one of the major sources of carbon-di-oxide emission. It constitutes about 5% of carbon-di-oxide emission globally. However, the demand for cement goes on surging and so carbon-di-oxide emission also goes on increasing which leads to the adverse effects on environment such as global warming. So the carbon-di-oxide emission should be either controlled with any other alternatives such as geopolymer cement or treated using carbon capture techniques such as bio-technical carbon capture. At the same time, no single technology can act as an only solution. Therefore, this paper deals with the portfolio of technologies that should be developed and deployed to address the increasing carbon-di-oxide emissions from the cement industry. This paper enhances a highly adaptable five techniques such as 1) Enzyme technology 2) Capture from precalcination of limestone 3) Geopolymer cement 4) Celitement 5) Kiln of granulation to cut down the carbon-di-oxide emission with process description, environmental and other benefits and costs. As a result, carbon-di-oxide emission can be restricted around 75% by employing these techniques.

KEY TERMS: Carbon capture, Geopolymer cement, Celitement, Fluidized bed kiln.

OBJECTIVE: The main objective of this paper is to reduce the enormous amount of carbon-di-oxide that are emitted from the cement industry as it constitutes about 5% of CO2 emission globally and goes on increasing as well.

1. INTRODUCTION:

Manufacture of cement involves quarrying and grinding of the raw materials which is then passed through a kiln in the form of a dry powder or wet slurry. This gives rise to the enormous emission of carbon-di-oxide. This emission, if untreated, leads to the adverse impacts on environment such as global warming. So it should definitely be treated by alternatives or emerging carbon capture technologies.

Hence this paper presents a novel approach for emerging alternative cement products such as geopolymer cement and celitement and carbon capture technologies such as bio-technical carbon capture and carbon-di-oxide capture from precalcination of limestone and kiln technology such as fluidized bed kiln. And it is likely that these five methods are highly adaptable to cut down the emission of carbon-di-oxide. This paper also deals with their process description along with their benefits and costs.

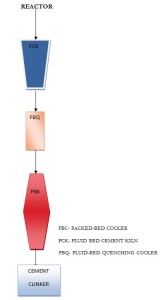

FIGURE 1: Reduction percentage of carbon-di-oxide

The above graph clearly depicts the reduction in the emission of carbon-di-oxide from the corresponding technologies.

|

TECHNIQUES: |

AMOUNT OF REDUCTION: |

|

Bio-Technical carbon capture |

30% |

|

Capture from precalcination |

38% |

|

Geopolymer cement |

25% |

|

Celitement |

50% |

|

Fluid bed kiln |

15% |

TABLE 1: Amount of CO2 reduction

This table shows the reduction percentage of carbon-di-oxide emission from the cement industry by employing the above mentioned five techniques.

2. EMERGING ALTERNATIVES FOR CEMENT PRODUCTS:

The following describes the emerging alternatives for cement products such as Geopolymer cement and celitement.

2.1 GEOPOLYMER CEMENT:

It tends to be the current innovative technology for the construction industry. It employs the minimally processed natural materials or industrial byproducts as binding agents. It is composed of a reactive solid component and an alkaline activator. Reaction with alkaline agent induces aluminosilicate polymer that gives the high compressive strength of the hardened product. Geopolymers are manufactured at relatively low temperatures at 7500 with the calcinations of aluminosilicates. Geopolymers can also be used for bridges and structural retrofits using geo-polymer-fiber composites.

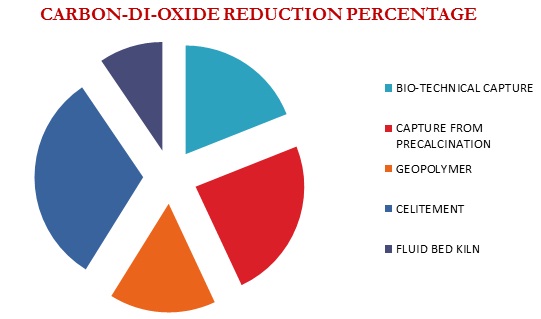

APPLICATIONS OF GEOPOLYMER:

FIGURE 2: 3D network of geopolymer

2.1.1 Environmental cost and other benefit:

• Significant potential energy and CO2 savings.

• It reduces about 25% of CO2 emission.

• Geopolymers generally depend on the minimal natural materials or industrial byproducts as binding agents.

• There is a constructive use of industrial byproducts.

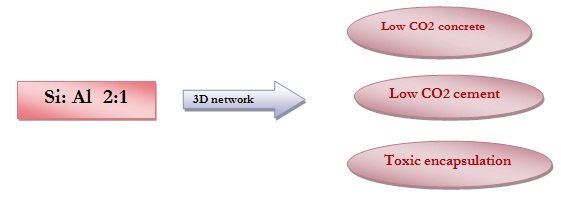

2.2 CELITEMENT:

Celitement is a hydraulic binder based on calcium hydrosilicates. It is a new family of cementitious binders. It belongs to the class amorphous hydraulic calcium hydrosilicates. Hardening involves the formation of Calcium Silicate Hydrate phases. Its raw material is carbonates and silicates. Carbonates are calcined before processing in an autoclave at 2000C. Calcium silicate hydrates are formed is mixed and milled together with remaining siliceous materials. During milling the hydrogen bonds are destroyed and new amorphous calcium hydro silicates are formed.

Figure 3. Composition of various hydraulic binders

2.2.1 Environmental cost and other benefit:

• It is similar to standardized cements.

• It could save up to 50% CO2 emission.

• Carbonate content is reduced significantly.

• Only half of the raw materials are thermally processed.

3. EMERGING CARBON CAPTURE TECHNOLOGY:

The following describes the technologies emerged to capture the carbon such as

1) Enzyme technology

2) Capture from precalcination.

3.1 ENZYME TECHNOLOGY:

Enzyme technology involves the biometric approach to capture the carbon-di-oxide using a biocatalyst and carbonic anhydrase. In general carbonic anhydrase is found in the lungs of mammals to manage carbon-di-oxide. Here it is used to create an industrial lung that captures CO2. After the waste carbon-di-oxide is captured, pure CO2 produced with the help of the enzyme and used in oil recovery. This patented process has three phases. First, flue gas containing CO2 enters the reactor where it is dissolved or captured in an aqueous solution. CO2 is then converted into a bicarbonate ion (HCO3-) in the presence of the enzyme. This bicarbonate-ion-enriched solution from the reactor is regenerated. The capture solution is reused in another cycle. The enzyme can materially lower the cost of carbon capture by allowing a reduction in the size of the absorber equipment and reducing process energy requirements.

CO2 + H20 <=>HCO3- + H+

3.1.1 Environmental cost and other benefit:

• Use of the enzyme increased CO2 removal by 30 percent.

• Use of the enzyme lowers capital and operating costs by allowing a reduction in the size of the absorber column and reducing total energy requirements.

• The enzyme can reduce energy consumption by increasing the CO2 transfer rate.

3.2 CAPTURE FROM PRECALCINATION:

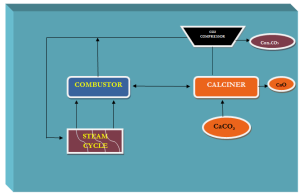

A precalciner produces CaO by dissociating CO2 from CaCO3 at high temperatures. The total CO2 produced in the precalciner is diluted within a larger exhaust stream making the CO2 capture so difficult. But this paper proposes a novel approach using superheated CaO in order to separate the calcinations and combustion at separate chambers. The heat needed by the calciner is supplied by the high temperature CaO particles that circulate them. By this arrangement CO2 can be collected in the calciner and compressed for storage as more than 50% of CO2 is from calcination.

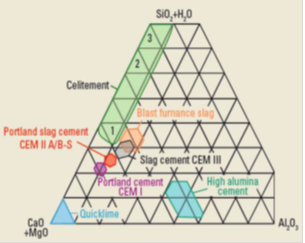

FIGURE 4 : process of precalcination

3.2.1 Environmental cost and other benefit:

• It could capture more than 45% of CO2 released in cement manufacturing.

• Avoids about 38% of the CO2 emitted in cement manufacturing.

• Employs moderate cost.

4 EMERGING KILN TECHNOLOGIES:

The following describes the fluidized bed kiln technology to make the energy more efficient and also to reduce CO2 emission.

4.1 KILN OF GRANULATION:

Granulation is a process acquired with fluid bed kiln that possesses a granulation control with granules 1.5 to 2.5 mm in diameter. It agglutinates the part of raw material powder to form a core and attaches other raw material around the core. It has a cylinder to calcine the raw materials in a fluid bed. An overflow at the top of the cylinder regulates the transfer of clinker to the cooling zone. It can be operated at low capital costs, lower temperatures, lower energy use and ability to accept a wide variety of fuels. It reduces the construction cost and installation area by 30%.

FIGURE 5: Granulation Process

4.1.1 Environmental cost and other benefit:

• Its energy is efficient.

• Low combustion temperatures.

• It needs less space.

• Though it is energy efficient, it reduces carbon-di-oxide emission.

5 CONCLUSION:

All the emerging energy-efficiency and low-carbon technologies presented in this report are alternatives to conventional production of cement and concrete or production of the conventional raw materials used in manufacturing cement or concrete. It is likely that no single technology will be the best or only solution but instead that a portfolio of technologies should be developed and deployed to address the increasing energy use and CO2 emissions of the cement industry.

Therefore, this report gives a portfolio of technologies that are highly adaptable for the reduction of carbon-di-oxide with energy efficiency.

6. ACKNOWLEDGEMENTS:

We are very thankful to YUVA ENGINEERS for giving us a platform to execute our paper. We would also like to thank our management who inspired us a lot for doing this work.

7. REFERENCES:

Abanades, C. 2008. Calcium Sorbent Cycling for Simultaneous CO2 Capture and Clinker Production. IPCC SRCCS 2005.

Argonne National Laboratory (ANL). 2003. Ceramicrete – technology Profile. Available at http://www.anl.gov/techtransfer/Available_Technologies/Material_Science/Ceramicrete/

Asia Pacific Partnership on Clean Development and Climate (APP). 2008. Industrial Recycling of CO2 from Cement Process into High-Energy Algal Biomass Coal Equivalent Fuel- Project Plan Summary.

Asia Pacific Partnership on Clean Development and Climate (APP). 2009. Energy Efficiency and Resource Saving Technologies in Cement Industry. Available at http://www.asiapacificpartnership.org/english/cement_tf_docs.aspx

Celitement, 2012. Available at http://www.celitement.de/en

Geopolymer Institute. 2012. Science – Chemical Structure and Applications. Available at http://www.geopolymer.org/science/chemical-structure-and-applications

Hamilton, T. 2008. A Concrete Fix to Global Warming- A new process stores carbon dioxide in precast concrete. TECHNOLOGY REVIEW – A Publication of MIT.

Kacimi, L., A. Simon-Masseron, S. Salem, A. Ghomari, Z. Derriche. 2009. Synthesis of belite cement clinker of high hydraulic reactivity. Cement and Concrete Research 39:559–565.

Rodriguez, N., R. Murillo, M. Alonso, I. Martínez, G. Grasa, J.C. Abanades. 2011. Analysis of a Process for Capturing the CO2 Resulting from the Precalcination of Limestone in a Cement Plant. Ind. Eng. Chem. Res. 50: 2126–2132.

Rodriguez, N., M. Alonso, G. Grasa, J.C. Abanades, J. C. 2008. Process for capturing CO2 arising from the calcination of the CaCO3 used in cement manufacture. Environ. Sci. Technol. 42 (18).

Roskos, C., D. Cross, M. Berry, J. Stephens. 2011. Identification and Verification of Self-Cementing Fly Ash Binders for “Green” Concrete. 2011 World of Coal Ash (WOCA) Conference – May 9-12, 2011 in Denver CO, USA. Available at www.flyash.info/2011/132-Berry-2011.pdf