Technical Paper Title: NANO GENERATOR

Authors: G.MAMATHA & G.HARITHA, 2nd BTech, EEE

College: Prakasam Engineering College, Kandukur

ABSTRACT:

Materials Science research is now entered a new phase where the structure and properties of materials are investigated, characterized and controlled at the nanoscale. Though as sophisticated as their larger counterparts, these devices are still burdened because they rely on an outside power. The size of the entire device is determined by the size of the power source. Batteries and other traditional sources are too large, and tend to negate the size advantages of nano devices. Also, batteries being used at present require toxic chemicals and have to be replaced periodically. To overcome these challenges; researchers are finding alternative ways to power nano devices. One promising development is the nano generator. In this talk, we specially emphasized application of nano generators, importance of nanowires in building a nano generator. Nanogenerator allows us to harvest or recycle energy from many sources to power these devices. The nanogenerators take advantage of the unique coupled piezoelectric and semiconducting properties of zinc oxide nanostructures, which produce small electrical charges when they are flexed.

KEYWORDS:

Nano wire, Low power miniature sensors, Piezoelectric effect, Electric power, VIBES (Vibration Energy Scavenging)

INTRODUCTION:

An array of zinc-oxide nanowires that generates current when vibrated with ultrasonic waves could provide a new way to power biological sensors and nano devices. Using ultrasonic waves to vibrate an array of zinc-oxide nanowires, researchers at Georgia Tech have made a tiny generator that can produce direct current. .By taking advantage of the fact that zinc-oxide nano

wires are piezoelectric, they converted mechanical energy into electricity. And by finding a way to collect electricity from multiple nano wires, the researchers took a big step toward a practical nano-scale power generator.

NANOWIRE:

Nanowires and other nano materials have shown great promise in creating future generations of electronic devices. New work from researchers at NIST, George Mason University, and Kwangwoon University in Seoul has generated a hybrid memory device that uses both conventional techniques and exploits the properties of silicon nanowires.

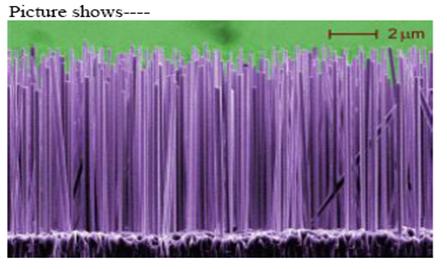

Electron micrograph shows the gallium nitride wires growing on a silicon substrate (color added for contrast.) The hybrid structure exhibited by these devices means that they are more reliable than other nanowire approaches, and they should be easier to integrate into modern components. The hybrid device that the team built is a non-volatile memory device similar to a flash device, which retains its memory even when power is turned off.The wires are generally between 30 and 500 nanometers (nm) in diameter and up to 12 micrometers long. When excited with a laser or electric current, the wires emit an intense glow in the ultraviolet or visible parts of the spectrum, depending on the alloy composition. The nanowires are grown onto an oxide nitride- oxide zinc substrate. When positive voltage is applied, electrons tunnel down into the substrate; when negative voltage is applied, the electrons tunnel back into the wires. When no voltage is present, the device can be read, and the position of the electrons will represent a “1” or a”0″.

WHAT IS A NANO GENERATOR?

Generation of electricity is necessary for some extremely small devices (nano devices) like medical devices, sensors and portable electronics without the need for bulky batteries or other energy sources. Instead of batteries, electricity for such devices would come, for instance, from muscle contraction or other body movements. Nano generator is one such device. Zinc oxide nanowires in nano generator produce electricity via a long-known phenomenon termed the piezoelectric effect. It occurs in certain materials, which change mechanical energy — from flexing or twisting, for instance — into electricity.

HOW IT WORKS:

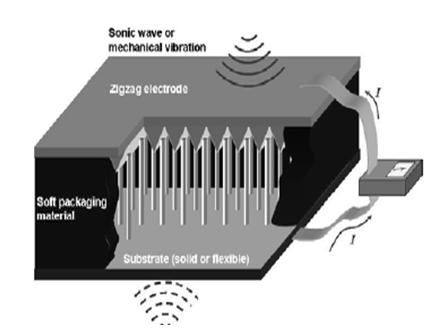

A key innovation that led to the nano wire generator is a new electrode design. Fabrication begins with growing an array of vertically-aligned nanowires approximately half a micron apart on gallium arsenide, sapphire or flexible polymer substrate.

Zinc oxide nanowires grown on a gallium nitride substrate.A layer of zinc oxide is grown on top of the substrate to collect the current. Also fabricated is a‘zigzag’ silicon electrode that contains thousands of nano-scale tips made conductive by a platinum coating. The electrode is then lowered on top of the nano wire array, leaving just enough space so that a significant number of the nano wires are free to flex with in the gaps created by the tips.Moved by mechanical energy such as waves or vibration, the nanowires periodically contact the tips, transferring there electrical charges. To vibrate the electrode, the researchers packaged the device, put it in water and exposed to the ultrasonic waves. As the zigzag electrode moves up and down, its peaks push and bend the nano wires, which generate electric current that the electrode collects simultaneously.

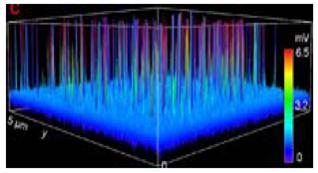

Compressing the wires or vibrating them left or right makes all the current add up in the same direction. By capturing the tiny amounts of current produced by hundreds of nano wires kept in motion, the generator outputs a direct current in the nanoampere range.

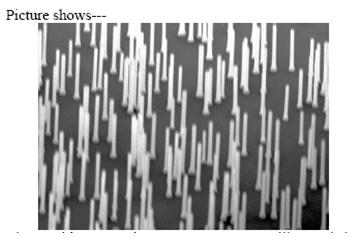

Before that happens, additional development will be needed to optimize current production. For instance, though nanowires in the arrays can be grown to approximately the same length — about one micron — there is some variation. Wires that are too short cannot touch the electrode to produce current, while wires that are too long cannot flex to produce electrical charge.

However, for real-world applications, the current generated by the nano generator needs to be higher and more stable. Wang’s research group is working on improvements toward that goal. . Wires that are too short cannot touch the electrode to produce current, while wires that are too long cannot flex to produce electrical charge. Right now, the nano wires are grown randomly, and the researchers estimate that anywhere between 250 and 1000 nano wires contribute to the current. This is less than one percent of all the wires in the array.

Researchers say that the next step is to grow a more regular array of nanowires that are uniform in size and height. Matching the nanowire pattern with the pattern on the electrode would utilize all the nanowires, increasing the current output and making it more stable. The research team also needs to increase the generator’s lifetime as it runs for a little more than an hour right now.

A graph showing spikes of electrical dischargeas the nanowires are scanned.

POSSIBLE APPLICATIONS:

The nano generator could provide a new way to power biological sensors and nano devices. It could drive them by making use of wind energy or liquid flow, eliminating the need for external batteries. Current battery technology limits the use of microelectromechanical sensors that measure cancer biomarkers, blood pH and glucose. The reason: as these sensors get smaller and smaller, conventional chemical batteries can’t keep up. Most of the time it’s the battery that’s big compared to the sensing part and it also runs out of power. Our bodies are good at converting chemical energy from glucose into the mechanical energy of our muscles. These nanogenerators can take that mechanical energy and convert it to electrical energy for powering

devices inside the body. The nano wire generator looks like a promising answer; it’s a small power source that doesn’t need refilling. One important application of the nano generator can be powering implantable biological sensors. Implanted in the body and driven by muscle contractions,blood flow or external vibrations transmitted through tissues, it could power the sensors.

FUTURE SCOPE:

Researchers expect that with optimization, thenano generator could produce as much as 4 watts per cubic centimeter based on a calculation for a single nano wire. This would be enough to power a broad range of nano-scale defence, environmental and biomedical applications, including biosensors implanted in the body, environmental monitors and even nano scale robots.

The team expects to make as many as millions or even billions of nano wires produce current simultaneously, which will allow optimization of operation of nano generator. Producing the top electrode as a single assembly sets the stage for scaling up this technology to power real nano scale applications. Before that happens, additional development will be needed to optimize current production by controlling the growth, density and uniformity of the wires. Because the chemical process by which the wires can be grown is inexpensive, at some point it may be practical to produce large arrays that are capable of providing enough power for consumer electronics. We can grow these on polymer substrates at very low cost, so that one day by placing these into people’s shoes we can generate electricity when walking.

To power a simple electronic device such as a diode or a transistor, the need is to raise the charge on the device from its current milli volt to at least half a volt. Thus, researchers plan to make the nanowires more uniform and stack multiple arrays as well as add capacitors to accumulate charge. Because zinc oxide is non-toxic and compatible with the body, the nano generators could be integrated into implantable biomedical devices to wirelessly measure blood flow and blood pressure within the body. They could also find moue ordinary applications in generating small current to power small body electronics. Finally, anything that makes the nanowires move within the generator can be used for generating power.